Your Partner in Water, Packaging & Domestic Products Manufacturing

Building Water, Print & Chemical Plants — Start to Finish.

Services

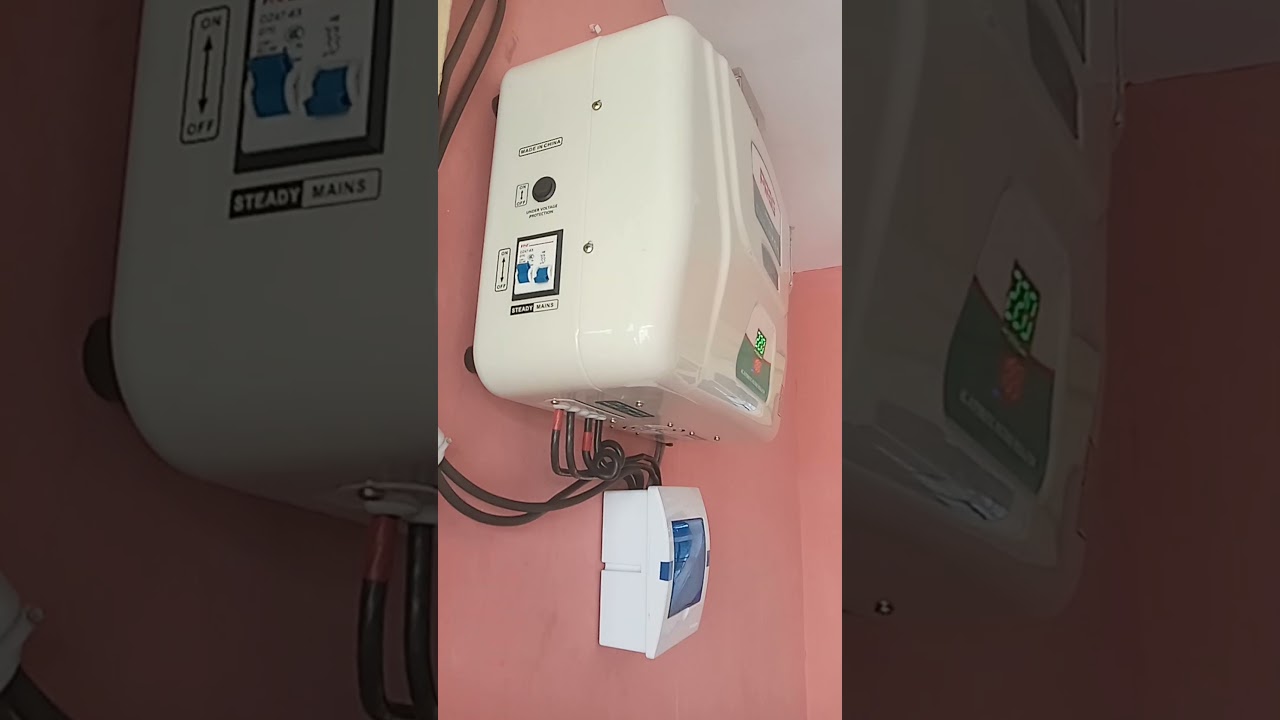

Water Treatment & Production Plant Setup

We provide everything you need to start and run your own water treatment and production (satchet and table water) plant. We setup small, medium and large-scale water production plants. We provide resources required for treating, producing and packaging satchet and/or table water, ensuring compliance with regulatory requirements.

Learn MoreFlexo Plate Manufacturing Plant Setup

We help setup flexographic plate manufacturing plant, equipped with the latest technology to provide precise, consistent, and high-quality custom flexographic plates for a wide range of packaging needs.

Learn MoreFlexographic Printing Plant Setup

We help manufacturers, brand owners and packaging converters set up turn-key flexographic printing plants that are efficient, scalable and compliant. From site selection and layout design to equipment procurement, installation, staff training and commissioning — we deliver a complete, documented, ready-to-run factory tailored to your production volumes, product mix (sachets, pouches, labels, cartons, bag-in-box, shrink sleeves) and budget.

Learn MoreSmall & Medium Scale Chemical Products Manufacturing Plant Setup

Delflow Industries Ltd offers end-to-end Plant Setup Services for small and medium-scale production of domestic and allied chemical products. Our services cover feasibility and market validation, regulatory compliance, process design, equipment procurement, plant layout, utilities integration, quality management, environmental & safety systems, operator training, and post-commissioning support. We focus on practical, cost-effective, and scalable solutions that meet quality, safety and environmental standards while minimising capital and operating costs.

Learn MoreRegulatory Compliance Assistance Services

Ensure your plant operates legally, safely, and efficiently. Delflow Industries Ltd provides end-to-end Regulatory Compliance Assistance Services for manufacturing and allied chemical businesses — from initial permitting and product registration to ongoing audits, training, and regulatory liaison. Our service is built for Nigerian and international requirements and is tailored for small and medium scale plants that need pragmatic, actionable compliance support.

Learn MoreQuality Control Services

Delflow Industries Ltd provides end-to-end Quality Control (QC) services designed to help manufacturers, packagers and suppliers deliver safe, compliant and consistently high-quality products. Our QC offerings combine practical on-site inspection, laboratory testing, systems development, and people-focused training to reduce defects, lower costs, and strengthen customer confidence. We design QC programs that fit small-scale operations through larger industrial plants across chemical, packaging, food & beverage, household products and allied industries.

Learn MoreHands-On Training Services

Practical, workplace-focused training that closes the gap between theory and production realities. Delflow Industries Ltd. delivers industry-grade, hands-on training services designed to upskill operators, technicians, supervisors and engineers so factories run safer, cleaner, and more profitably.

Learn MoreOur Plants

Flexographic Plate Plant

Our state-of-the-art Flexographic Plate Plant is equipped with the latest technology to provide precise, consistent, and high-quality custom flexographic plates for a wide range of packaging needs.

Learn MoreFlexographic (Nylon) Printing Plant

Unlock vibrant and durable printing solutions with our advanced rotogravure/flexographic nylon printing solution for water, polythene bags, bread factories and others.

Learn MoreWater Treatment & Production Plant

With us, you can enjoy the convenience of having fresh, premium quality water (satchet & table water) delivered to your doorstep on a regular basis.

Learn MoreSoap Plant

Discover the power of natural ingredients combined with expert craftsmanship at our Soap Plant. Our soaps are carefully formulated to promote the best cleaning solutions.

Learn MoreMain Categories

New Arrival

Courses

Blog

A strong Quality Assurance/Quality Control (QA/QC) workflow ensures products meet specifications and regulatory standards at every stage of production. Effective QA/QC in manufacturing is built on a comprehensive Quality Management System (QMS) that aligns with international standards (ISO 9001:2015 for quality, ISO 22000/FSSC 22000 for food safety, ISO 14001 for environmental, ISO 45001 for safety, etc.).

Free Downloads

Process Improvement & Root Cause Analysis (RCA) Techniques

Process Improvement & Root Cause Analysis (RCA) Techniques

Process Capability

Process Capability

Acceptance Sampling & Acceptance Quality Limit in Quality Control

Acceptance Sampling & Acceptance Quality Limit in Quality Control

Achieving Quality Excellence with PPAP & APQP

Achieving Quality Excellence with PPAP & APQP

Before Setting up a Quality System

Before Setting up a Quality System

Benchmarking: Business Process Improvement Methodology

Benchmarking: Business Process Improvement Methodology

Cellular Manufacturing Systems

Cellular Manufacturing Systems

Digital Manufacturing & Paperless Quality Management

Digital Manufacturing & Paperless Quality Management

Failure Mode & Effect Analysis (FMEA)

Failure Mode & Effect Analysis (FMEA)

Food Safety & Risk Management Concepts

Food Safety & Risk Management Concepts

Pareto Analysis for Process Improvement

Pareto Analysis for Process Improvement

Document Control Master List

Document Control Master List

Equipment Maintenance Schedule Template

Equipment Maintenance Schedule Template

Prioritization Matrix

Prioritization Matrix

Spaghetti Diagram

Spaghetti Diagram

HSE Risk Register

HSE Risk Register

The 8 Dimensions of Quality in Manufacturing

The 8 Dimensions of Quality in Manufacturing

Achievements

Testimonials

Management Team

Adebayo Olanrewaju

Founder & Chief Engineer

Adebayo Olanrewaju is a multi-skilled Chartered Chemical Engineer, COREN registered engineer, author and entrepreneur with over a decade of experience in the manufacturing industry and consulting services.

James Ayila

Co-Founder

James Ayila is a seasoned mechanical engineer with series of hands-on experience in plant design and operations. He holds a masters degree in mechanical engineer from Purdue University, USA.

Jack Smith

Business Development Manager

Jack Smith is a seasoned business administrator with cutting experience across various sectors, including manufacturing and finance. He holds a master's degree from University of Lagos.

Lucy Lennon

Head, People & Culture

Lucy Lennon is a human resources professional with over a decade experience in personnel management across various organizations in Nigeria and beyond. She holds a bachelor's degree and various certifications in human resources management.

Customer Service

- 1, Olorunsola Street, Ado Odo Road, Alapoti, Atan, Ota, Ogun State, Nigeria

- +234-7037710839

- +234-7085829369

- info@delflow.org

- Mon-Fri - 08:00-05:00